Coating (Painting)

As a preision CNC machining services supplier, the end workpieces should meet functional requirements such like durability or scratch resistance, and aesthetic appearance. The application of coating can be decorative, functional or both to meet your requirement.

The color, features and desired functions of workpieces are to determine which of the following coating operations to be used in Apporo.

Liquid Coating

As a precision CNC machining services supplier, the workpieces should meet functional requirements such like durability or scratch resistance, and aesthetic appearance. The application of coating can be decorative, functional or both to meet your requirements. The color, features and desired functions of workpieces are to determine by the coating operations to be used by our coating partner.

Generally speaking, color change capability is a major advantage of liquid coating. As for liquid coating systems, we can be easily designed for quick color changes by regulating Lab color space which can describe mathematically all perceivable colors in the three dimensions L for lightness and a and b for the color-opponents green-red and blue-yellow. It means, with liquid paint, the color can be mixed on site to given specifications.

Powder coating

Powder coating, different from liquid coating, can provide functional requirements with not only better durability, scratch resistance, withstand outdoor conditions and also great aesthetic appearance. Similar to liquid coating, the application of powder coating is usually for decorative, functional or both to meet your requirements.

The color, features and desired functions of workpieces are to determine by the coating operations to be used by our coating partner. Below showed the special effects used in most of our powder coating project:

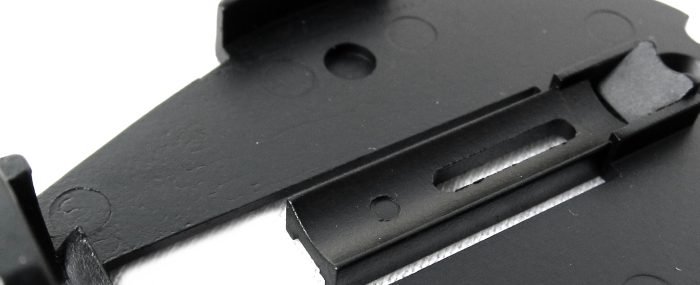

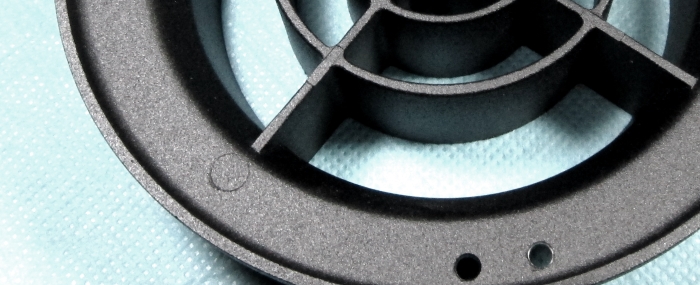

1.) Plain type powder coating

2.) Hammer type powder coating

3.) Texture type powder coating

4.) Wrinkle type powder coating

Electro Deposited Coating

Electro deposited coating, also named electrocoating, electrophoretic coating, or electrophoretic painting is to deposit the pigments or dyes onto an workpiece. The process is useful for applying materials to any electrically conductive CNC machining parts. The workpieces which are being deposited by electro deposited coating will be featured with:

- Less friction

- Uniform/even coating

- Wear resistance

- Anti-corrosion resistance

- Environmentally Friendly, RoHS compliance