Why Choose APPORO CNC Services?

Our CNC Machining Services Advantages

CNC machining services at Apporo are a vital part of modern manufacturing processes, providing high precision, accuracy, efficiency, and flexibility. These services are used in various industries, including aerospace, automotive, medical, and electronics. With their numerous benefits and wide range of applications, CNC machining services are essential tools for any manufacturing company looking to produce high-quality parts efficiently and cost-effectively.

CNC stands for Computer Numerical Control, a technology used to control and operate machines with high precision and accuracy. CNC machines are commonly used in the production of various parts and components across different industries. In this article, we will explore the benefits of CNC machining services and how they can be utilized in various industries.

• High Precision and Accuracy

One of the significant benefits of CNC machining services is their ability to produce high-precision, accurate parts. CNC machines can operate within a tolerance of just a few microns, ensuring that the finished product is of high quality and meets the required specifications.

• Increased Efficiency

CNC machining services can produce parts quickly and efficiently. Once the program is set up, the machine can produce multiple parts with the same level of accuracy and consistency, making it an ideal choice for mass production.

• Flexibility

CNC machines can be programmed to produce parts in various shapes and sizes. This flexibility allows for the production of custom-made parts for specific applications, making CNC machining ideal for industries such as aerospace, automotive, and medical.

• Cost-Effective

CNC machining services offer a cost-effective solution for producing high-quality parts. Although the initial investment in the machine is significant, once set up, it can produce a large number of parts with consistent accuracy. This reduces the need for manual labor and lowers overall production costs.

Quality Assurance and Professional Testing

As a trusted CNC services manufacturer, we are committed to continuous improvement and staying at the forefront of technological advancements. We invest in ongoing training for our employees, regularly review and update our quality management systems, and embrace innovative solutions to enhance our manufacturing capabilities.

In addition to our internal quality control measures, we also collaborate with third-party testing laboratories and certification bodies to validate the performance and reliability of our facilities. These external partnerships provide unbiased assessments of our manufacturing processes and ensure that our products meet the highest industry standards.

1.Quality Assurance and Professional Testing

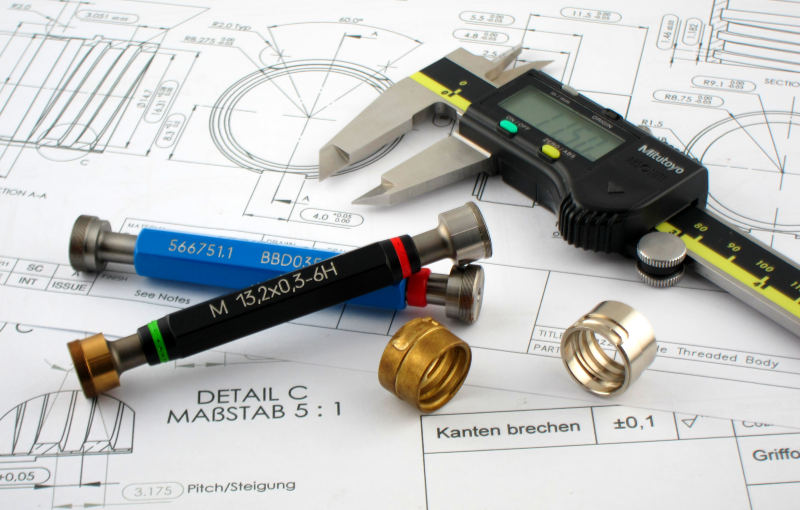

Every item we produce undergoes rigorous equipment calibration and verification processes to guarantee accuracy and precision. To maintain consistency and accuracy, we employ a comprehensive quality control system throughout the entire manufacturing process. Each production step is carefully monitored and inspected, from initial design and programming to machining and final assembly. Our dedicated team of quality assurance professionals conducts thorough checks and tests at various stages to identify and address any potential issues promptly.

Inspection Equipment:

- Sheffield Cordax Discovery D-8 DCC CMM

- Brown & Sharpe Hexagon Metrology CMM

- Vision Measuring Machine

- Baty R14 Profile Projector

- Other Inspecting, Measuring and Testing Equipment

2. Strict Quality Control Process

Nothing is more important than production quality. As a professional CNC machining manufacturer, we have established a critical SOP for our quality control process, as outlined below. Generally speaking, we define four steps in the quality inspection process for each production run. The inspection items usually include incoming raw materials, the machining process, and finished CNC machining parts.

Quality Control Process:

- IQC (Incoming Quality Control)

- IPQCS (In Process Quality Control Section)

- FQC (Final Quality Control)

- OQC (Out-going Quality Control)

3. Non-destructive and destructive testing

In the field of manufacturing and engineering, both non-destructive and destructive testing are essential techniques used to assess the quality, integrity, and performance of materials and products. These testing methods play a crucial role in ensuring the safety, reliability, and compliance of various industries, including aerospace, automotive, construction, and more.

Professional CAD Drawing Services

We offer professional CAD drawing services to meet the diverse needs of our clients across various industries. With our expertise in computer-aided design (CAD) software and a team of skilled drafters and engineers, we provide accurate and high-quality drawings for a wide range of applications.

By leveraging our professional CAD drawing services, you can benefit from improved design visualization, enhanced communication, and increased efficiency in the manufacturing or construction process. Our accurate and comprehensive drawings serve as valuable references for project planning, production, and documentation.

1. 2D and 3D CAD Drawings

Using the latest CAD tools and technologies, we create detailed and precise 2D and 3D drawings tailored to your specifications. Whether you require architectural drawings, mechanical designs, electrical schematics, or any other type of technical drawings, we have the expertise to deliver exceptional results.

2. Part Design and Engineering Drawings

Our part design and engineering drawing services cater to a wide range of industries, including automotive, aerospace, consumer products, industrial equipment, and more. Whether you need a simple component or a complex assembly, we have the expertise to deliver high-quality designs and drawings tailored to your specific needs.

By utilizing our part design and engineering drawing services, you can benefit from optimized part performance, efficient manufacturing processes, and streamlined production. Our commitment to precision, innovation, and customer satisfaction drives us to deliver designs and drawings that meet the highest standards of quality and functionality.

3. System Integration and Component Design

We specialize in system integration and component design services to help businesses streamline their operations and enhance the functionality and performance of their products. Our experienced team of engineers and designers works closely with clients to develop efficient and cohesive systems while ensuring optimal integration of individual components.

Our system integration and component design services cater to a wide range of industries, including automation, telecommunications, robotics, energy, and more. We have experience working with diverse technologies and platforms, enabling us to deliver customized solutions that align with specific business requirements.

Professional Surface Treatment Consultation

We provide expert consultation services for surface treatment, helping businesses select and implement the most suitable surface finishing techniques for their products. With our in-depth knowledge and experience in the field of surface treatment, we offer guidance and recommendations to achieve the desired aesthetics, functionality, and durability.

Based on your requirements, we offer expert advice on the selection of surface treatment techniques. This may include recommendations for processes such as painting, electroplating, anodizing, powder coating, galvanizing, passivation, or specialized coatings. We consider factors such as material compatibility, cost-effectiveness, durability, and aesthetic appeal to ensure the chosen treatment meets your expectations.

Our consultation services also cover surface preparation methods, which are essential for achieving optimal adhesion and quality of the surface treatment. We provide guidance on techniques such as cleaning, degreasing, surface roughening, and pre-treatment processes to ensure proper surface preparation before applying the chosen treatment.

Post Processing:

- Grinding

- Coating (Plating)

- Plating

- Other post processing

ISO 9001 Certification

APPORO CNC ISO9001 Certification : Success is the sum of small efforts - repeated day in and day out.

RoHS and Safety Certification

At APPORO, we believe that QUALITY is everything for a CNC machining service supplier. We apply a Quality Control Process to continuously improve our standards. Depending on the part profile and dimensions, each CNC machining project comes with a tailored quality control plan. Essentially, we can provide the following quality inspection reports:

Quality Inspection Report:

- Material Certification

- Part Drawing with Marked Item Numbers

- Quality Inspection Report

- SGS Report for RoHS Compliants

- Surface Treatment Report

- Plating Report