Post Processing

Introduction

As a precision CNC machining services supplier, a wide variety of machines are used for workpieces post processing to meet functional or decorative requirements generally listed as below:

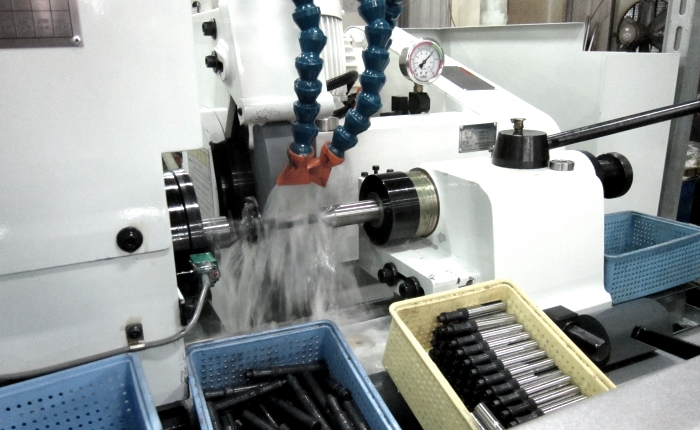

1.) Grinding

A grinding machine is used to complete or modify a component that must be featured with high surface quality (e.g., low surface roughness) and high accuracy of shape and dimension.

The size, shape, features and desired production rate of workpieces are to determine which of the following grinding operations to be used in Apporo:

- Surface Grinding

- Outside Diameter Grinding

- Centerless Grinding

- Through Feed Grinding

2.) Coating (Plating)

The end workpieces should meet functional requirements such like durability or scratch resistance, and aesthetic appearance. The application of coating can be decorative, functional or both to meet your requirement.

The color, features and desired functions of workpieces are to determine which of the following coating operations to be used in Apporo:

- Liquid Coating

- Powder Coating

- Electro Deposited Coating

3.) Plating

Electroplating is to deposite a metal on a conductive surface of CNC workpiece. Some of benefits for plating include: increased resistance to corrosion, improved hardness, superior strength, resistance to wear, improved IR reflectivity improved ductility, improved solderability, improved paint adhesion, altered conductivity and for other purposes.

Different plating chemicals incorporated into the process deliver anything from a semi-bright and fully bright cosmetic effect, matte or satin finishes.

- Nickel Plating

- Chrome Plating

- Zinc Plating

- Black Oxide

- Anodizing

4.) Other post processing

- Chamfer and Bevel

A chamfer as a beveled edge of a hole, frequently cut at a 45° incline to the 'normal' surface to breaks a sharp edge. Compare to chamfer made at a 45° angle to the adjacent principal faces, whereas bevel is a sloping edge between two principle faces.

- Sandblasting

Abrasive is dosed into the stream of high preseure compressed air and gets a acceleration in the outflow from the blasting nozzle to against a metal workpiece surface to smooth a rough surface, roughen a smooth surface, shape a surface, or remove surface contaminants. It is widely used in different industries, such as: automotive industry, metal-manufacturing industry, foundry, aviation industry, shipbuilding, production of various welded structures, etc.

- Tapping

Thread tapping is available in our machining processing, including CNC milling or CNC turning parts, metal or plastic hardwares, electronic industry, automobile and motorcycle industry, sanitary equipment, electrical and air power tools, plate for outer case, computer parts, secondary machining process in press machine, etc.

Post processing we provide?

- Automatic Sawing Machine x1

- Surface Grinding Machine x2

- Cylindrical Grinder x2

- Special Purpose Machine x5

- Assembly Machine x6

- Sealing Machine (Manual) x4

- Sealing Machine (Automatic) x1

- Thread Rolling Machine x1

- Magnetic Grinding Machine x1

- Vibration Grinding Machine x1

- Sieve Filter x1

- Heat-Treating Machine x1

- Centrifuge x1

- Pad Printing Machine x1

- Taping & Strapping Machine x1

- Blade Sharpening Machine x5