CNC Lathe Machining

What is CNC Turning Machining?

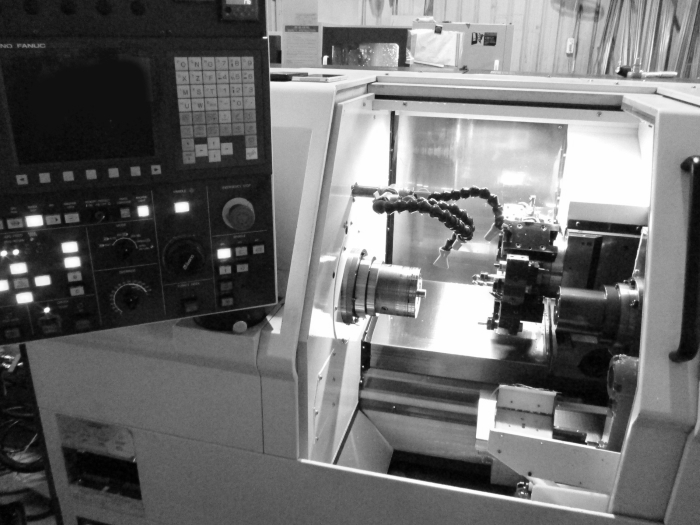

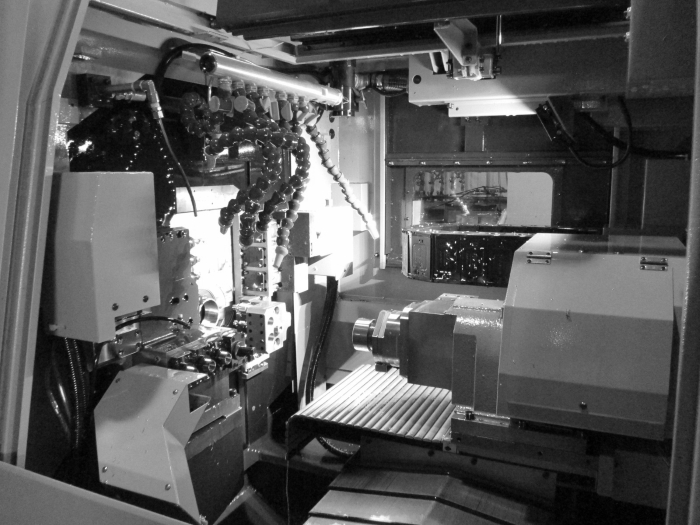

CNC Turning machining, a machining cutting tool which fixed and rotated the raw material rod on it's driving headstock, to remove the material by means of relative movement between various cutting tools and raw material rod.

Automatic CNC Turning Machine can be combined with specific CNC machining operations, such as turning, threading, boring, drilling, grooving, reaming, cutting, facing, parting, knurling, etc.

Precision Manufacturing CNC machine with computer numerical control(CNC) could be a powerful machine integrated with highly precision CNC control, automatic feeders, coolant systems, translation/rotary systems, etc.

Apporo mainly operated with highly precision Japan and Taiwan CNC Turning Machining Center, such like Nomura, Star, Moriseiki, Miyano, Takisawa, Chiah Chyun, etc, basically generalized into Fixed Head and Sliding Head Turning/Lathe Machining Centers for various purpose.

Is my part a good fit for CNC Turning Machining?

There are some things to determine if a part can be made most cost-effectively on a CNC Turning machine:

What is the largest OD on the CNC machining part in comparison to the production quantity?

If a part is under 65mm OD, it may be suitable for higher volume mass production (over 1000 pieces). If it's larger than 20mm OD, the part will need to be chucked individually while in CNC machining, then it's most competitive for lower quantity work, such as prototypes.

Could my CNC machining part be run on a Swiss Screw Machine?

If the CNC machining part is under 20mm OD and high volume(over 5,000 pieces), it will be suitable to run on a Swiss Screw Machine(so called CNC Automatic Turning/Lathe Machine) with much more cost effectively and also highly precision.

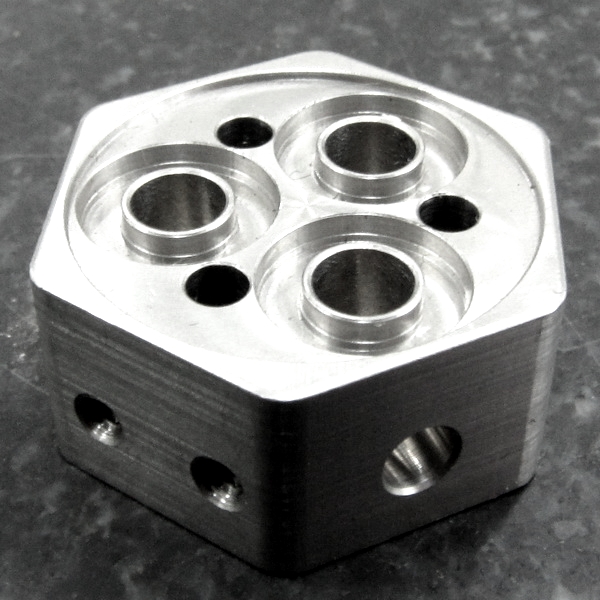

CNC Turning Lathe Machining Capability

Outer Diameter: 1-100 mm

Overall Lengths: 500mm

Tolerance: ±0.002 mm ( equal to 2 μm )

CNC Turning Lathe Equipment

| Turning Machine Centers | RPM | Capacity | |

| Nomura UB7-20 with 4th axis | 10,000 | ø20 x 200 | |

| Nomura UB7-25 with 4th axis | 10,000 | ø25 x 200 | |

| Nomura NN-10CS with 4th axis | 10,000 | ø10 x 100 | |

| Nomura NN-16B III with 4th axis | 8,000 | ø16 x 110 | |

| Nomura NN-20U III with 4th axis | 10,000 | ø20x200 | |

| Nomura NN-20J2 with 4th axis | 10,000 | ø20 x 200 | |

| Nomura NN-25YB with 4th axis | 8,000 | ø25 x 200 | |

| Mori Seiki NL-1500 with 4th axis | 6,000 | ø356 x 515 | |

| Chiah Chyun CB-36M with 4th axis | 6,000 | ø36 x 485 | |

| Nomura NN20-H | 10,000 | ø20 x 200 | |

| Nomura NN20-B II | 10,000 | ø20 x 200 | |

| Takisawa NEX-110 | 3,500 | ø400 x 675 | |

| Takisawa TC-20 L | 4,500 | ø250 x 640 | |

| Takisawa EX-308 | 4,000 | ø260 x 530 | |

| Takisawa EX-310 | 4,000 | ø350 x 710 | |

| Takisawa EX-108 | 4,000 | ø320 x 530 | |

| Takisawa EX-110 | 3,000 | ø495 x 400 | |

| Takisawa NEX-108 | 4,000 | ø320 x 481 | |

| Takisawa NEX-110 | 3,500 | ø400 x 657 | |

| Takisawa HT-108 | 3,000 | ø330 x 510 | |

| Takisawa HT-110 | 3,000 | ø330 x 510 | |

| Takisawa TC-20 | 4,000 | ø250 x 550 | |

| Takisawa TC-2m II | 3,500 | ø550 x 600 | |

CNC Milling Machining Capability

Dimension: within 300 x 300 x 300 mm

Tolerance: ±0.002 mm ( equal to 2 micrometer )