Design Matters (Part 2) - Coating2018-07-02

Previously on Case Study we discussed material shrinkage as an important factor to be considered in the design before production. Apart from material shrinkage, there are still far more factors you have to be aware of in your design. That being said, devil is in the details. Especially when designing an assembly part, you have to pay extra attention, or assembly failure can be foreseen. Coating then is a topic worth a discussion.

Coating refers to applying substance to the surface of a part. The purpose of it includes protection, adhesion, decoration and so on. Based on the purpose, there are different types for selection, eg. teflon coating, titanium nitride coating, powder coating. As coating is to add a layer to a part, the dimensions of it will be likely to change.

So, to prevent coating from significantly impacting the function of your part, Apporo offers two tips below for your drawing:

1.) Indicate clearly on your drawing if the dimensions are BEFORE or AFTER surface finish. Take powder coating for example. The thickness typically ranges from 0.10 mm to 0.30 mm, which can hugely affect the dimension of a part.

2.) Take notice of uneven coating situation. Take powder coating as an example again. There are generally three main issues as below which may result in uneven powder coating:

• Powder spray is uneven.

• The workpiece and the spray gun are too close.

• High voltage output instability. Besides, parts with a good path to earth ground but without no appreciable resistance will have better surface quality.

Case Study on Powder Coating

Recently Apporo manufactured a batch of avionic bezels for our customers, which were to be assembled with LCDs. When the customer received the bezels, they found some of them fail to fit the LCDs. Initially, we thought the problem was caused by machining method. The bezels were die casting manufactured, so the quality of them would not be the same as those CNC machined. To dig into the problem, our customer sent us an inspection aide, which is of the same design as the assembly LCD. After receiving the inspection aide and looking into it, Apporo figured out that the actual problem was powder coating. Here is our findings:

1.) The distance between two surfaces that needed to be assembled with the LCD was only 0.11 mm. However, there was a step on the inspection aide, the height of which was 0.25-0.27mm. This definitely would have influences on the assembly.

2.) The drawing indicates that all dimensions are prior to finish. As we said previously, the thickness to powder coating is typically around 0.10 mm to 0.30 mm. After coating process, the distance would shrink so as not to fit the LCD well.

How We Improve the Assembly Issue?

Because the design of the LCD could not be revised, we could only fix the mold or have an extra process to machine the bezel. However, after detailed reviewing the modification, it was not practical to replace the mold core. Actually, the inlet gates were just located at the bottom edge of bezel. If we modified the mold core, we should have to modify the slide at the same time. In that way, the modification cost would be extremely expensive, almost equal to building another new mold. Eventually, we decided to remove the extra material from the back side after casting but before powder coating.

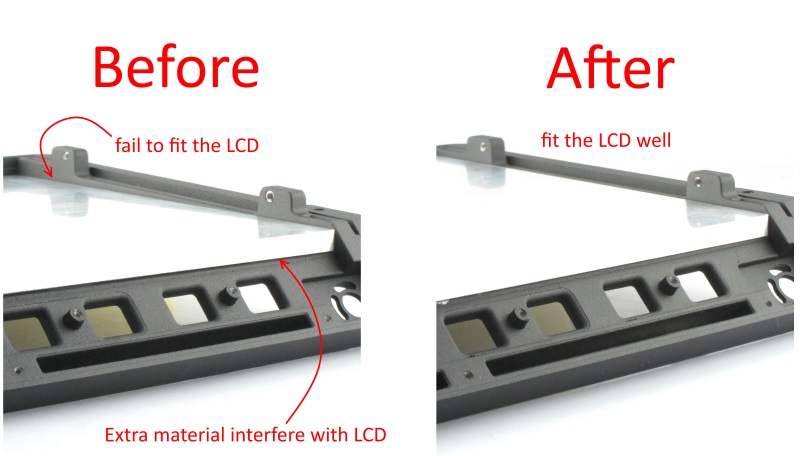

Remove the extra material to fit the LCD well.

Before(LEFT): Extra material interferes with LCD. The Bezel fails to fit the LCD.

After(RIGHT): The Bezel fits the LCD well after the extra material is removed.

This case fully shows the importance of design. If you need your powder coating on your part, make sure you take the dimension changes from surface treatment into consideration. Need some professional suggestions before production? Contact Apporo now. This is going to be one of the best decisions ever in your life!

More Case Study on Coating: Aluminum Anodizing Coating Failure