Diamond Knurling Operation on CNC Lathe2018-04-26

As mentioned previously in "Cross Knurling Profile DIN 82-RGV", knurling is a manufacturing process to feature straight, crossed, angled, diamond-like lines or pattern onto the CNC components. Usually, we use DIN 82 knurling specification standard for most CNC machining cases. If diamond knurling is required, we shall use DIN 82-RGE which is featured with diamond-like 30° cross male knurling. Also, we may consider DIN 82-RGV which is featured with cross knurling pattern as an alternative for customized purpose.

Case Study for Diamond Knurling

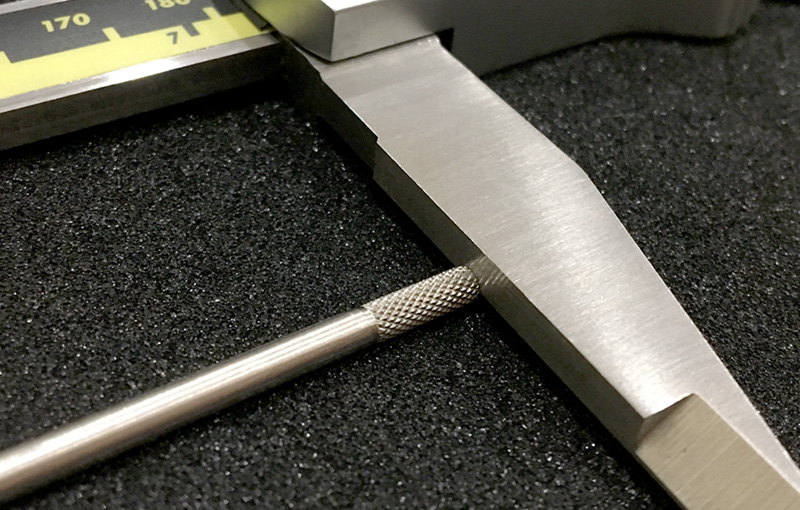

Recently, one of our customers turned to us because of their oversized parts. The overall length of this shaft on the drawing was supposed to be between 183.10 ~ 183.20 mm. However, our customer found the total length of some parts was up to 183.30 mm, which was beyond the tolerance. We then discussed with our customers and analyzed that the root cause was diamond knurling.

Door Hinge Shaft with Diamond Knurling

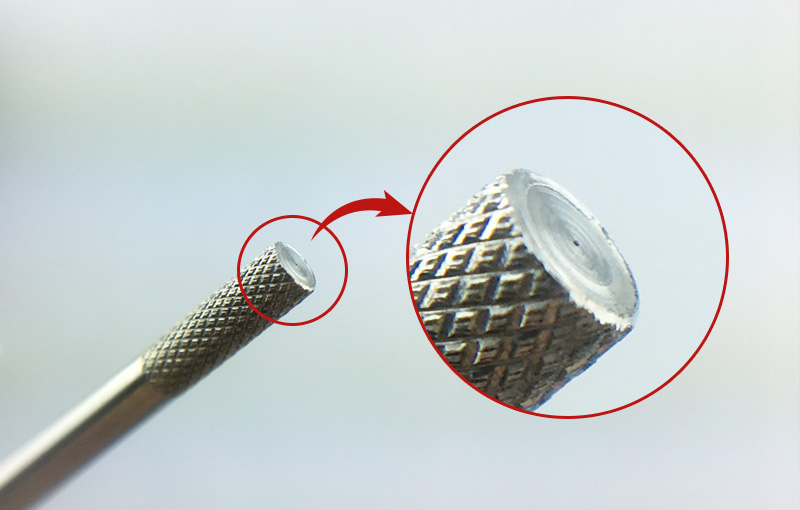

According to the shaft photo above, slight plastic deformation happened at the knurled end. Generally speaking, the plastic deformation is related to feed rate and force of knurling wheel on work spindle. After repeated trial and error, we can control the OD of knurling to be within the tolerance .128" +/-.001".

Plastic deformation after diamond knurling at one end

Total length of some parts was beyond the tolerance.

How We Solve The Oversize Situation?

As for the increase of the total length, it also resulted from knurling. To solve this problem, we decided to cut the total length to be lower limit of tolerance, let's say 183.10 mm. After the shafts were knurled at one end, the total length did slightly increase, but were still within the tolerance. According to our machining experience, the increase of total length should be less than 0.05 mm. In summary, regarding this problem, we have two solutions as below:

1.) precisely remove the extra length at the knurled end.

2.) chamfer the knurled end to remove the extra length.

Besides, according to ISO-2768mK(*Ref.1), the tolerance of such length should be +/-0.50 mm. So, the tolerance of the total length on the drawing actually brought much more difficulties for the manufacturing process. All in all, if you have relevant inquiries, we recommend you to send us your drawings first for technical discussions. Through the discussions, we can find a way to bridge your design and CNC manufacturing together. Trust us and we will turn your design into a real part perfectly!

*Ref.1: See more about ISO-2768