Other Services

Stamping

Stamping Parts Production Lines

As a one stop shop for all machining services supplier, we had invested stamping factor with high speed press, mechanical press and pneumatic press ranged from 3T to 110T, including one dual spindle 110 tonage pneumatic stamping machine, to offer our clients a variety of stamping production services such as deep drawing, blanking, bending and etc.

Furthermore, we are also capable of NCT automatic punching, laser cutting, laser welding services to extended our stamping production lines capability.

What is a Stamping Part?

A stamping part machined by stamping mold is used to form the metal into shape by blanking, piercing, drawing, bending, embossing. Both single stage stamping mold or progressive stamping mold can produce the required metal form via every stroke of the press.

Single stage stamping mold featured with simple structure and lower cost is designed and built for single stamping operation in general.

Progressive stamping mold is featured with set of dies for various stamping operations in a row where a metal strip went through one stage per punch. However, a progressive stamping mold is more expensive than single stage one, usually recommend for high throughput product or complex workpiece. Contact our team for project review, our engineer will check and advice in detail.

-

Stamping-Deep Drawing

Kind of sheet metal forming process of stamping, is to radially drawn the sheet metal into forming dies by continuously mechanical action of several punches. It is thus a shape transformation process with material retention. The process is determined "deep" drawing when the depth of the drawn part exceeds its diameter.

-

Stamping-Blanking

A shearing cutting process of stamping, featured by a punch and a die to define the hole profile on metal sheet.

-

Stamping-Bending

To produce V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly metal sheet.

Stamping Material availability:

| Copper | OFC, C11000 | |

| Brass | C2680 | |

| Phosphor Bronze | C5191 | |

| Stainless Steel | 304, 316 | |

| Aluminum Alloy | 5052 | |

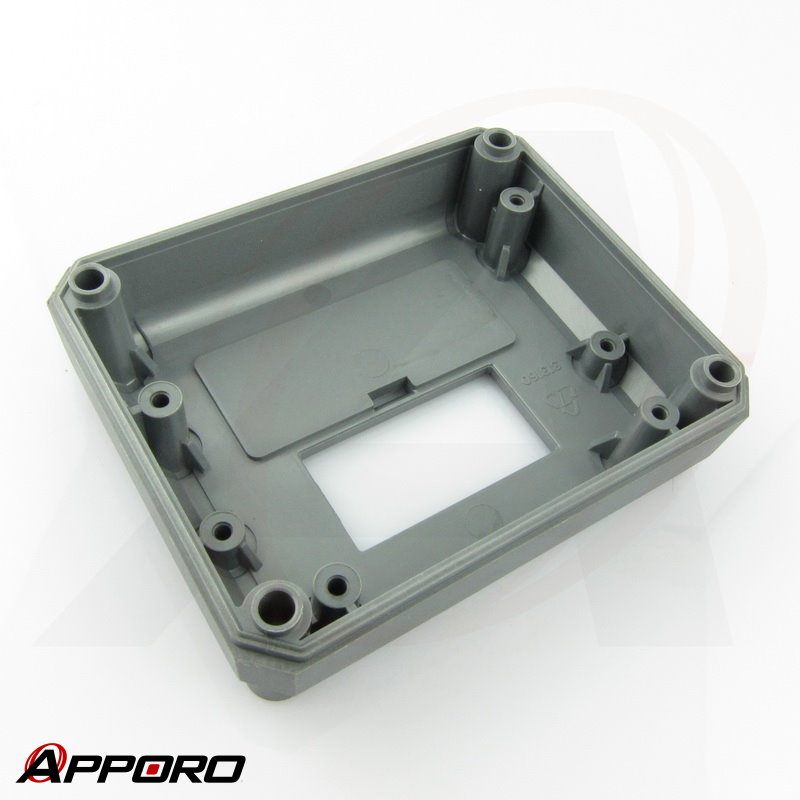

Plastic Injection

To inject hot melted plastic resin into a mold cavity for consistently producing workpieces by repeat molding process: Injected liquid phase plastic resin ⇒ solidified in a cooling phase ⇒ ejected by ejection pins.

Material availability:

| Plastics | ABS, Nylon(PA, PA66), PS, PP, PE, POM(Delrin), PPS, PEEK, TPR, etc. | |

To get a free project review for your precision plastics injection molding parts? Contact us!

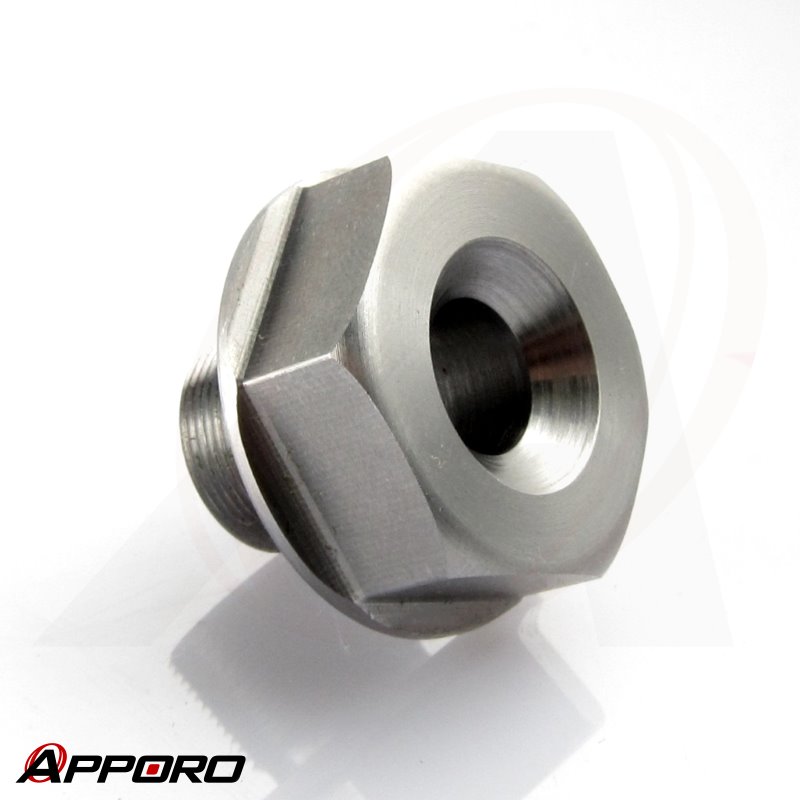

Die Casting

Aluminum Die Casting

A356, ADC 10, ADC 12

Zamak

In Addition To CNC Machining Services

Despite of parts made from CNC machining, an instrument or machinery could be assembled with much more kind of spare parts. For example,

- frame chassis, support structure made of metal sheet, produced from stamping machine

- electrical insulator, chassis of instrument or chemical resistance container made of plastic, produced from plastic injection molding

- electronic connectors/housings, light shell/heatsink, device bracket made of aluminum, manufactured from die casting molding

As an one stop shop for all parts manufacturing services, tooling for plastic injection, die casting and stamping services. The R & D team at Apporo have marvelous manufacturing experience and knowledge which our clients usually comment how gorgeous our machining workmanship is.

Stamping, Casting and Injection Molding Compare To CNC Machining

CNC machining is not the only way for large scale precision parts mass production. We also offer various of production method to enhance our core services:

- Stamping

- Manufacturing parts from metal sheet which is supplied with limited kinds of thickness.

- Parts features could be formed in each single step with quick frequency.

- Progress stamping mold is highly recommend for high speed, complex, or tiny parts production.

- Much more cost-effective compare to CNC manufacturing process on large scale mass production.

- Deep drawing mold can offer a much flexible manufacturing method for sheet metal forming.

- Aluminum die casting

- An alternative metal forming production for 5-axis CNC prodution, but parts will feature with off-mold angle at its internal or external surface.

- Feasible for thin shell, heat sink, complex profile parts production.

- Much more cost-effective compare to CNC machining process on large scale mass production.

- Capable of various kind of surface treatment, such like nickel plating, electroless nickel plating, powder coating, liquid coating.

- Production speed of aluminum die casting can be much higher.

- Injection molding

- An alternative plastic forming production for 5-axis CNC production, but parts will feature with off-mold angle at its internal or external surface.

- Much more cost-effective compare to CNC machining process on large scale mass production.

- Production speed of injection molding can be much higher .

- Capable of manufacturing parts made of thermoplastic compound which offers excellent colorability, clarity, flexibility, and elasticity.

Apart from the above, parts manufactured via CNC could be generally stronger and have much better production quality and finish. Eventually, CNC machining is typically used from early to late stages of project development whenever parts are ready to be sample tested for functional accuracy or mass production.

Customers who also checked:

|

|

|

|

||||

| Aluminum Die Casting | Brass Turned Parts | CNC Turned Parts | Precision Plastics Injetion |