Analytical Chemistry

Production for Analytical Chemistry

Fully supporting our customers who are well known and worldwide leader in the development of electro-analytical, gas sensor system, electrode instrumentation, including customized spare parts for below analytical chemistry equipment:

1.) pH meter, ORP electrodes, ISE

2.) Gas analyzers, gas sensors

3.) Multiparameter meters

4.) ICP emission and mass spectrometers

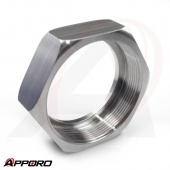

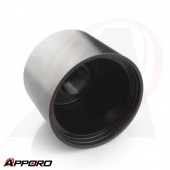

Material available in: Aluminum Alloy 6061-T6, 7075-T6, ADC 12, Stainless Steel, Carbon Steel, Plastic, Zamak.

All the products are RoHS Compliant and proudly Made In APPORO, Taiwan.

CNC Machining in Electroanalytical Equipment

To ensure the accuracy and reliability of pH meters, ORP electrodes, and ISEs, some products or components require precision manufacturing using CNC machining. CNC machining is a process that involves removing material from a workpiece using precision cutting tools, guided by a computer-controlled program. It is essential to create precise hole and surface shapes for these components, as the accuracy of these components directly affects the accuracy of the analytical chemistry equipment they are used in.

Electroanalytical equipment, such as pH meters, ORP electrodes, and ISEs, require high-precision components to ensure their accuracy and reliability. CNC machining is a process that uses computer-controlled cutting tools to remove material from a workpiece, creating precise hole and surface shapes that are crucial for these components.

CNC Machining for pH Meters

For pH meters, electrodes consist of an electrode body, electrode assembly, and cable assembly. Materials such as glass, ceramic, or plastic require CNC machining to create precise holes and surface shapes for the electrode body. The electrode assembly needs CNC machining to ensure precise contact surfaces, such as the reference electrode and electrolyte. The cable assembly requires CNC machining for precise connectors and plugs to ensure good electrical contact and signal stability.

CNC Machining for ORP Electrodes

ORP electrodes have an electrode body, reference electrode, and working electrode. CNC machining is necessary for the electrode body and electrode assembly to ensure accurate hole and surface shapes. The reference electrode and working electrode also need CNC machining for precise contact surfaces and surface shapes to ensure high-precision potential measurements.

CNC Machining for ISEs

ISEs typically have an electrode body, reference electrode, and ion-selective membrane. The electrode body requires CNC machining for accurate hole and surface shapes. The reference electrode requires CNC machining for precise contact surfaces and surface shapes, ensuring high-precision potential measurements. The ion-selective membrane needs CNC machining for precise thickness and hole sizes to ensure high selectivity and sensitivity.

The Importance of Precision in Electroanalytical Equipment

The accuracy and precision of electroanalytical equipment directly affect their performance. Precision components made with CNC machining can ensure the accuracy and reliability of these instruments.

When choosing a CNC machining service provider, it is important to look for a company with experience in producing high-precision components for analytical chemistry equipment. A reliable service provider can help ensure the accuracy and reliability of your electroanalytical equipment.

By using CNC machining to create precise components for electroanalytical equipment, manufacturers can ensure the accuracy and reliability of their products. In conclusion, CNC machining is critical to the production of pH meters, ORP electrodes, and ISEs. The accuracy and precision of these components are vital to the analytical chemistry equipment’s performance. Therefore, it is necessary to use CNC machining for the production of these components to ensure their accuracy and reliability. If you require high-quality precision manufacturing using CNC machining.