Beware the Silent Saboteur: Tumbling Finishing Might Be Undermining Your Work!2024-12-20

Tumbling, also known as vibratory finishing, is frequently used in the post-processing of CNC machined parts to remove sharp edges and burrs. However, the narrow groove edges might have been deformed due to the impact from tumbling, causing the groove width to shrink and making it impossible to assemble the C-clip.

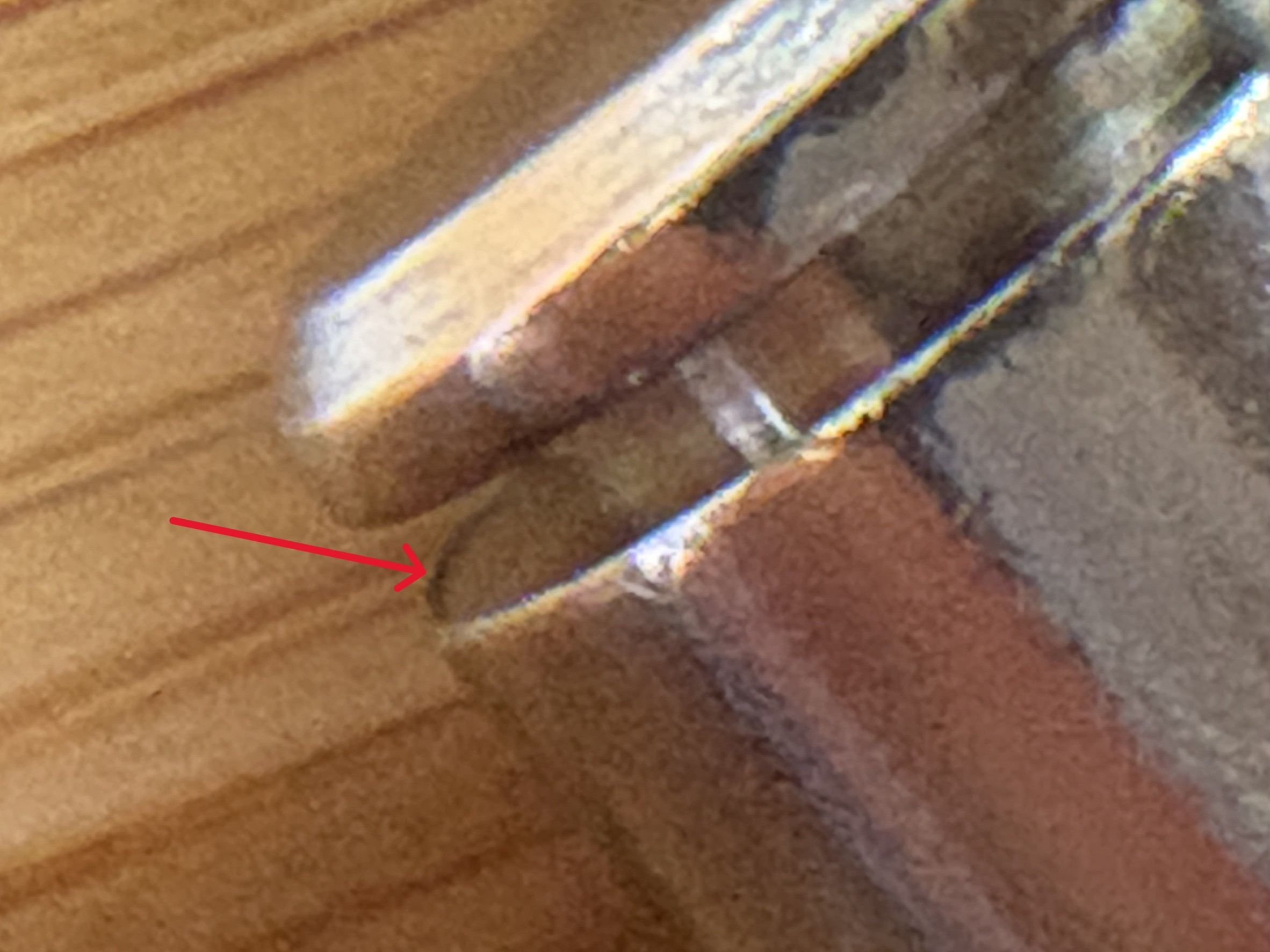

The image above shows the deformation at the edge highlighted by the red arrow.

To address this issue, the following improvement plan has been proposed:

・Increase the Chamfer Size

Design a larger chamfer on the edges to accommodate for any potential deformation during the finishing process, ensuring the slot remains adequately sized for the C-clip.

・Cease Tumbling

Originally, tumbling was used to deburr and break the sharp edges. If vibratory finishing is ceased to prevent the unwanted deformation, the part must be machined with a chamfer on the lathe to deburr.

・Increase Tolerance

Adjust the groove dimensions to include a wider tolerance on the upper limit, or suggest to the customer to slightly increase the groove width to ensure assembly with the C-clip.

By implementing the above changes, we aim to prevent similar issues in the future, ensuring parts are machined to specification and can be assembled as intended.