How Does CNC Machining Service in Taiwan Climb the Ladder of Success?2021-02-22

Since the late nineteenth and early twentieth century, globalization has gradually led to international trade, capital and investment flows, migration, and the knowledge dissemination. From the Q&A below, let’s take a look at how Taiwan as a west Pacific island country reaches such outstanding achievements in the CNC machining industry, which blooms and stands out from the intense competitions of globalization.

- The origin of CNC machining service in Taiwan

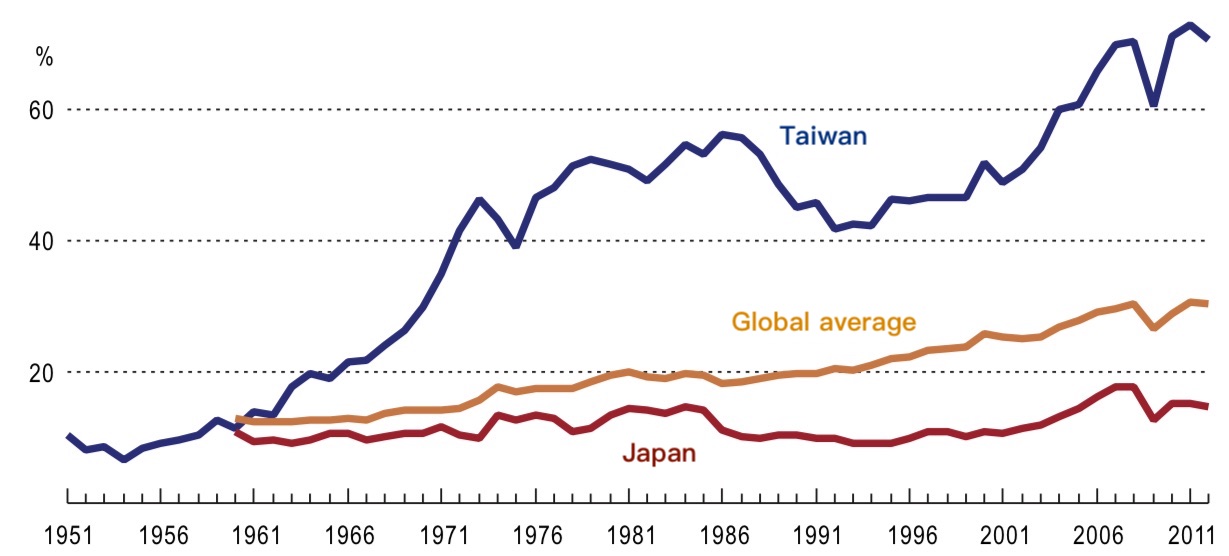

1950-1980 is a period called “Taiwan Economic Miracle”, when Taiwan benefited from the late-development advantage of industrialization. The industrial globalization after WWII enabled multinational corporations to look for lower-cost manufacturing bases worldwide. Therefore, with low labor rates and production lines, economics in Taiwan began to prosper, led by the manufacturing industry that processed and exported.

Export-oriented Economic Growth

- The strength of CNC machining service in Taiwan

The Industry of CNC machining service is quite dense in Taiwan. It features convenient transportation, vertical integration of services from raw materials, fine machining to surface treatment and so on, and horizontal integration of services, providing casting, forging, rolling, extruding, cutting, high energy beam machining, chemical etching, etc. Therefore, the industry of CNC machining service Taiwan is more capable of product structure breakdown and integration, allowing highly flexible manufacturing efficiency.

- The future of CNC machining services

Due to the breakthrough of Internet of Things (IoT) concepts and techniques, automatic control and wisdom management will play an important role in the industry of manufacturing:

1.) Multi-axis CNC machines with high performance and precision with data analysis, automatic corrective feedback to increase the efficiency of high precision machining.

2.) CAD softwares to complete component modeling and machining procedures to shorten the time from design to finished product, and to also increase the flexibility of production lines.

3.) CNC machines with sensors to measure online, collect production data, optimize plant activation, and overall capacity.