Rack Marks on Anodized Aluminum Parts2016-05-30

What is Aluminum Anodizing?

In general, oxidation process is likely to damage or weaken most metal parts. However, the oxidation process for aluminum alloy named aluminum anodizing can increase the ability of strength and anti-corrosion. The anodized parts have to be treated over four major processes: pre-clean, anodizing, dye and seal. You can also read our previous case study to understand more about aluminum anodizing. Today, we are talking about rack marks shown on most of anodized aluminum part. What are rack marks? And, how do they happen? After knowing what rack marks are and how they happen, you also have to know how to make the marks invisible.

Why scratch-like marks on my aluminum parts?

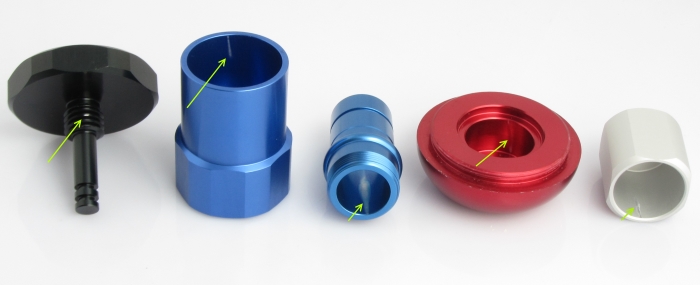

Have you ever seen the scratch-like marks inside the hole or on the thread of the CNC aluminum milling parts? We call the scratch-like mark a rack mark in the anodizing process. We use the customized jig for holding aluminum part as a conductor between electrode and CNC machined aluminum part for anodizing. Once anodizing process is completed, the operator will remove the aluminum parts from the tight holding jigs. Therefore, there will be a small area without anodizing layer surrounded by the holding jigs, just as the same as the marks shown in below photo.

Rack Marks on Anodized Aluminum Parts

How to minimize the rack marks on the anodized machined parts?

Frankly speaking, there is no way to remove the rack marks. But, you can make it invisible or minimize the rack marks in anodizing process. For example, you can use threaded rods or bolts into existing threaded holes for contact purpose. Or, you could ask the anodizing operator to squeeze the holding jigs onto the parts which will be covered or invisible in future application. Actually, some of our important clients did ask us to squeeze the holding jigs onto the noted position of the CNC aluminum parts.

When you are designing an aluminum part which needs anodizing identifying on your drawing where the part can be racked will be helpful for the anodizer. If you have any project about CNC machining aluminum parts, you are welcome to send us RFQ for free project review.