Revolutionizing Bushing Production with Cost-Smashing Powder Metallurgy2025-09-09

Recently, a client of mechanical assemblies for machinery applications contact us for a custom iron square tube bushings to serve as spacers for elevating component thickness. Each bushing measured 10.0 mm x 10.0 mm in cross-section (length and width), 10.0 mm in height, and 1.0 mm wall thickness, forming a hollow square profile suitable for load-bearing and alignment purposes. Initially, the production approach involved sourcing standard 3-meter-long iron square tubes (already matching the 10.0 mm x 10.0 mm dimensions) from material suppliers. These were then processed as follows:

1.) Wire EDM (electrical discharge machining) to fabricate custom CNC lathe fixtures for secure holding.

2.) CNC Automatic lathe operations to clamp the square tube and cut it to the precise 10.0 mm height.

3.) Deburrs, oiling and packaging

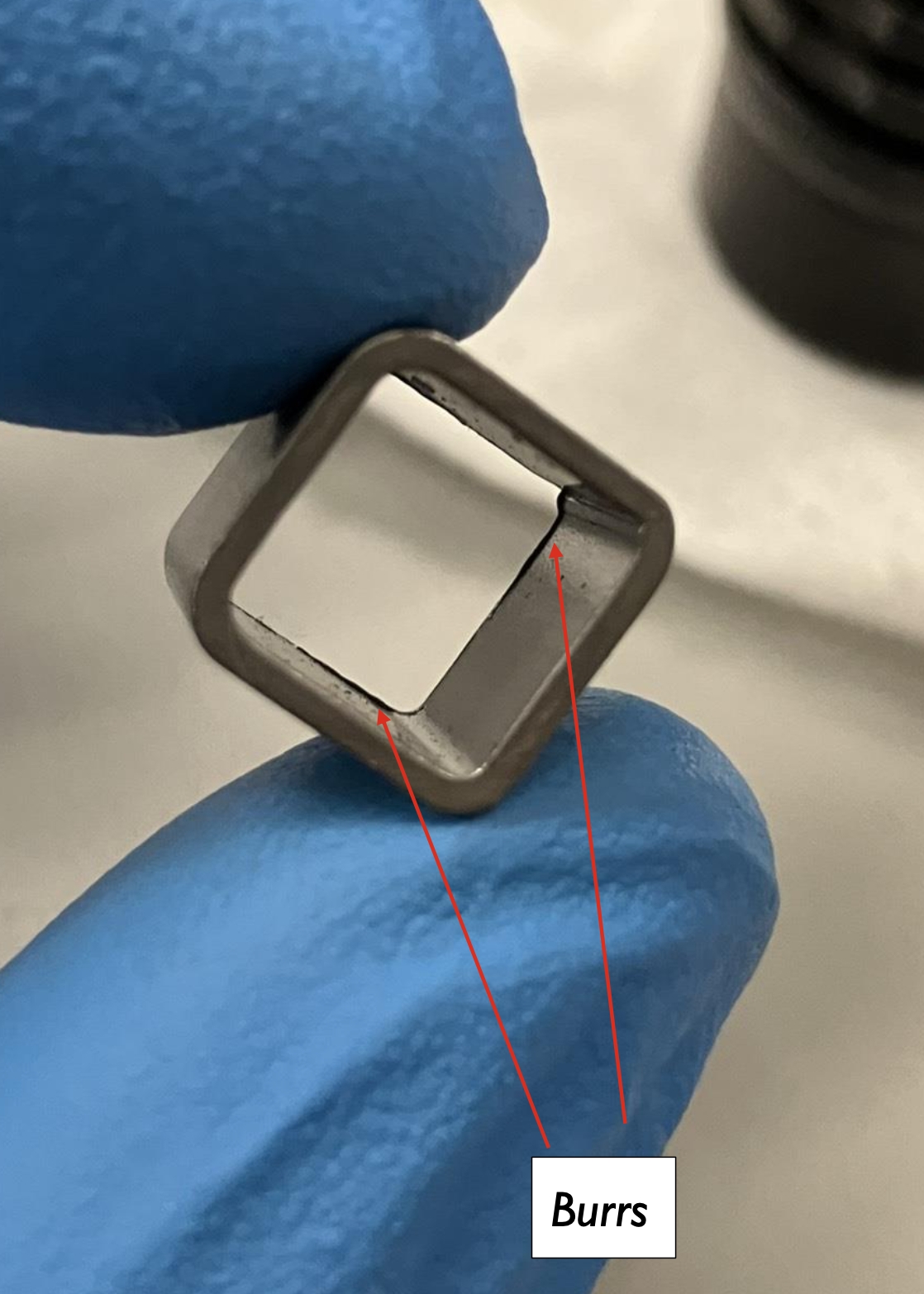

This method was selected for its apparent simplicity and low material costs, leveraging readily available stock to minimize custom fabrication. However, during initial testing, our engineering team identified critical defects in the lathe-cut edges. The parting tool on the automatic lathe left burrs—small, raised metal protrusions—along the hole edges of the square profile. These burrs compromised the bushing's performance by potentially causing misalignment, wear on mating parts, or interference during insertion into assemblies.

Burrs found inside inner tube

Below shows the way our team look for mitigating the burrs:

1.) Secondary Lathe Refinement

Clamping the cut face in the lathe's tailstock (back spindle) and using a drill bit to deburr the opposite hole edge only addressed the boundary of a circle. The sharp corners of the square profile remained inaccessible to the drill, necessitating manual filing consequently. This labor-intensive step not only increased cycle times but also required an additional set of customized square fixtures for the tailstock—fabricated via costly wire EDM—adding significant setup expenses.

2.) Tumbling

Introducing a tumbling process with abrasive media was considered to automate deburring. However, tests showed it was ineffective for the thin-walled geometry; instead of removing burrs, the abrasive media compressed them inward, reducing the internal square hole width below tolerances (e.g., from 8.0 mm to 7.6 mm or less). This distortion risked functional failures, such as binding in the assembly.

The production approach above, while feasible for low volumes, proved inefficient and unreliable at scale, potentially inflating the costs due to rework and risk of scrap.

Transition to Powder Metallurgy

Considering an annual demand of 6,000-10,000 pieces of this bushing, also based on Apporo's decades of accumulated manufacturing experience, the engineering team evaluated alternative processes and recommended powder metallurgy (PM) as a superior, cost-saving option. PM involves compacting iron powder into a mold under high pressure, followed by sintering (heating to fuse particles without melting), to produce near-net-shape parts.

Tube made of Powder Metallurgy (Left) and CNC machining cut (Right), side by side comparison

The client, upon reviewing the cost models, expressed strong interest. PM resolved supply variability—ensure consistent 1.0 mm wall thickness and 10.0 mm dimensions—while simplifying logistics by eliminating long-tube handling and cutting. Let's summerize the benefits and outcomes below:

1.) Cost Savings

Mold investment recouped within two years; overall per-unit savings of 40-50%, enabling the client to improve margins without quality trade-offs.

2.) Process Efficiency

Reduced from 5-7 steps (sourcing, fixturing, cutting, tumbling, deburring) to 3 (molding, sintering, inspection), cutting lead times by 60% and labor by 80%.

3.) Quality and Reliability

Burr-free parts and no dimensional drift from batches. Enhanced repeatability supports just-in-time delivery.

4.) Client Feedback

The solution aligned with the client's need for "High Quality, Low Cost, and Fast delivery" production. As they noted, partnering with Apporo provided an economical, stable alternative that transformed a problematic process into a competitive advantage.

This case exemplifies how Apporo's innovative proposals turn manufacturing challenges into opportunities for efficiency and partnership. For similar consultations, contact our engineering team. Apporo's expertise in adaptive manufacturing not only met immediate needs but positioned the client for scalable growth.