Design Challenges and Improvements for Threaded Component Assembly2025-08-08

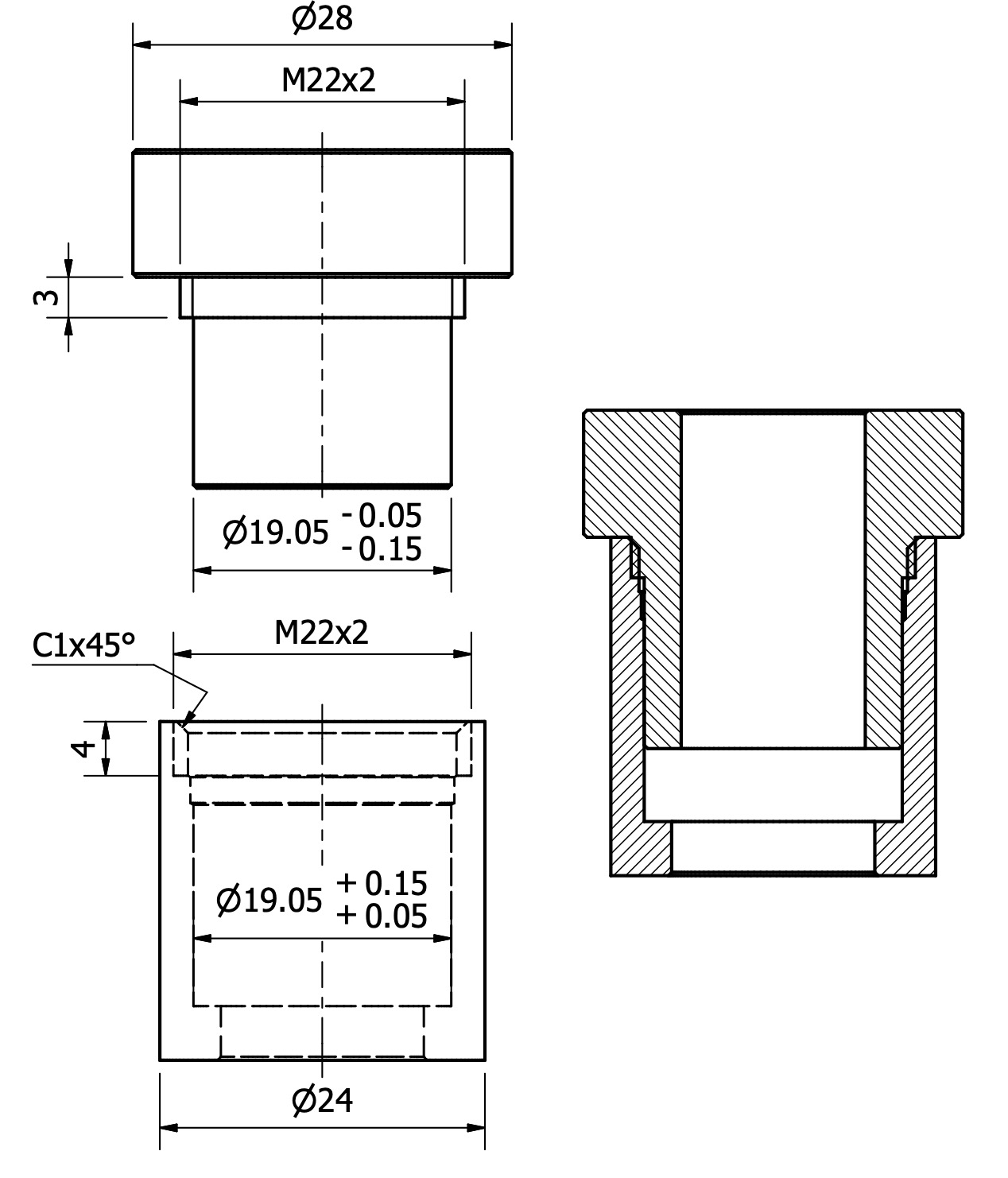

In a recent project, a client specified a design for a CNC machining component featuring an M22x2.0 external thread with a thread length of only 3.0mm, equals approximately 1.5 thread turns. The thread base connects to a larger outer diameter, and initially lacked a thread relief (runout) groove. This component is intended to be screwing into an internal threaded mating part.

Threaded component assembly by using improper thread may result in interference and out of function

Problem Statement

The design presented two primary issues that could compromise the functionality and reliability of the assembly:

- Insufficient Thread Length: When considering incomplete threads (chamfered at the start or imperfect threads at the end), the effective thread engagement may be reduced to ONLY one turn or less. This limited engagement could significantly weaken the connection, reducing the assembly's strength and reliability during operation.

- Lack of Thread Relief Groove: Without a relief groove, the external thread may not fully engage with the internal threaded component, preventing a secure and complete connection. During assembly, the transition from the threaded section to the larger outer diameter can cause interference with the internal thread, preventing full engagement. This could result in improper seating, increased stress concentrations, or even damage to the threads during assembly.

- Inadequate Thread Turns: Industry standards from ISO or ASME typically recommend a minimum thread engagement of at least 1 to 1.5 times the thread diameter for sufficient strength, which would be approximately 22–33mm for an M22 thread. With only 3.0mm of thread length, the effective engagement is inadequate, particularly when factoring in incomplete threads.

Proposed Improvements

To address these issues and enhance the component’s performance, the following solutions are proposed:

- Increase Thread Length: Increase the thread length to at least 6.0mm (approximately 3 turns for M22x2.0) to ensure sufficient engagement for a strong, reliable connection.

- Add a Relief Groove: Incorporate a relief groove at the thread base where it meets the larger outer diameter. This allows the external thread to fully engage with the internal thread without interference.

- Enlarge Chamfer on Internal Thread: A larger chamfer at the entrance of the internal threaded hole accommodates incomplete threads or runout on the external thread, ensuring smoother assembly and reducing the risk of thread damage.

- Redesign Thread Specification to M21x1.5: Given sufficient space in the inner and outer diameters of both components, modify the thread specification to M21x1.5. This finer thread pitch allows more thread turns within the same length (e.g., 6.0mm would yield 4 turns), significantly improving engagement and connection strength.