Cross Knurling Profile DIN 82-RGV2016-05-23

After CNC fabrication processing, the machined workpiece is usually with smooth metal surface. However, to better grip with hands/fingers, or for plastic injection insert and decoration purpose, it is common to have parts knurled. Knurling is a manufacturing process to feature straight, crossed, angled, diamond-like lines or pattern onto the CNC components. Sometimes, we also machine multiple shallow slots or polygonal for same purposes. DIN 82 is most commonly used knurling spec in CNC machining services. Each subcategory of it then corresponds to a specific knurling feature. Take DIN 82-RGV, DIN 82-RBR/RBL, and DIN 82-RGE for example. DIN 82-RGV is with cross knurling pattern. DIN 82-RBR/RBL is with right/left hand spiral. DIN 82-RGE is with diamond-like 30° cross male knurling.

Ref: Standard specification of DIN 82

Poor Cross Knurling Quality

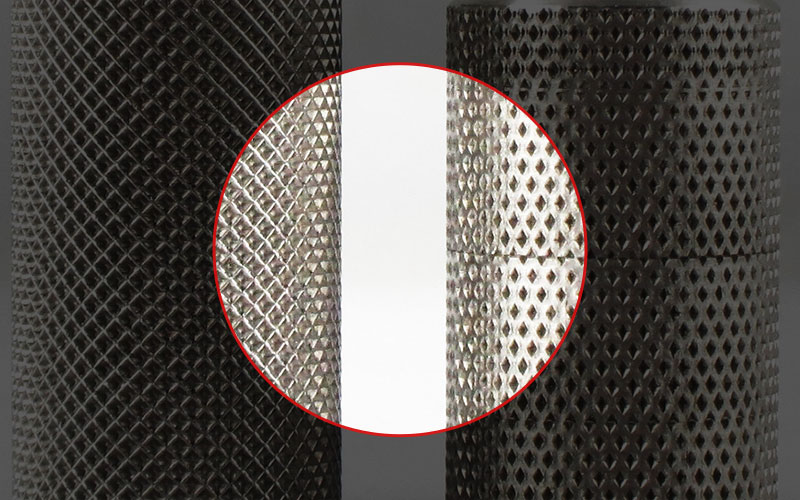

Our customer once sent us the original sample made of stainless steel 304. The sample manufactured by their previous local prototyping manufacturer was with poor knurling surface quality. See the shorter item in below photo. The dimensions of sample are precise and within the required tolerance, but the knurls are dissatisfactory. They are with improper length, too light pattern. Also, these knurls lack lead-in chamfers around the threaded holes.

Cross Knurling DIN 82-RGV Compare Zoom-in

Obviously, the appearance of the shorter part does not look good because of the improper length of knurling. However, a customized full length cross knurling tool can solve this issue. Regarding the pattern, it was too light probably due to the CNC programming or CNC lathe limitation, but we are able to conquer this issue as well. Moreover, based on our techniques , the lead-in chamfers around threaded hole are not a hard task for APPORO either.

Improved knurling

Therefore, we ordered a customized full length knurling tool to meet the required pattern spec of DIN 82-RGV 0.8. Apart from that, the automatic Japaneses CNC turn-mill machines also helped improve the quality of surface and dimensions. Above photo shows the longer workpiece machined by APPORO has the better knurling pattern.

We can offer CNC precision parts with several types of knurling surface, such as straight knurling, cross knurling, and diamond-like knurling. We are also capable of knurling on plastic precision parts. If you have related knurling inquiries for your parts, kindly send us RFQ for free project reviewing without hesitation.