Anodizing Troubleshooting: Uneven and Blotchy2016-11-24

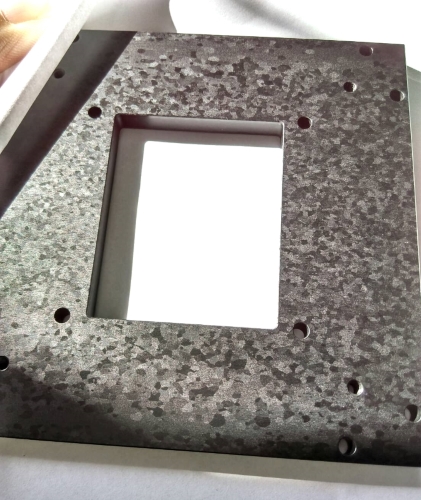

Recently, our US client commented on our latest shipment of CNC milling aluminum anodizing parts. All the part profile dimensions are okay, except that the surface of the part was blotchy and not shiny, sharp as before. Our client tried to wipe a part with alcohol to see if the surface appearance improved, but it did not work. The photo below showed the part surface.

Blotchy Spots on Anodized CNC Aluminum Part Surface

How the blotchy spots happened?

According to our production experience in the past, blotchy spot randomly happened to various batches of aluminum raw material. From raw material to machining procedures, the blotchy spot was not observable till anodizing.

The grain boundaries or dendrites looking blotchy spots might have happened due to uneven current density across the surface of the part. The blotchy spots were with a higher current density than the surrounding area. High current density raised the temperature locally and degraded the surface finish. Chemical reaction during anodizing could also create this kind of blotchy spots.

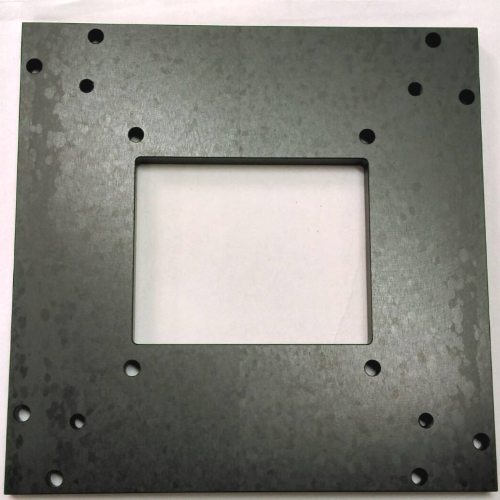

Uneven Anodizing CNC Machining Aluminum Parts

How to avoid the blotchy and uneven anodizing?

To avoid this situation from happening, we will ask supplier to pre-anodize the aluminum raw material. Then, they will provide us with batches of material free from blotchy mark after anodizing. Please MUST inform us if your workpieces are for customer use or cosmetic surface requirement.

Moreover, you can take a aluminum alloy panel and cut it into several pieces. Then, respectively blast, buff, and polish one piece and leave one with nothing done to it. Black hard anodize all the pieces at the same time and note that all the pieces above will come out differently due to the finishes. Sometimes, pre-treatments above are work and can modify the surface well.

If you are interesting in APPORO's production capability, please visit our official website or send us RFQ for free project reviewing.